![]()

Contents Hide

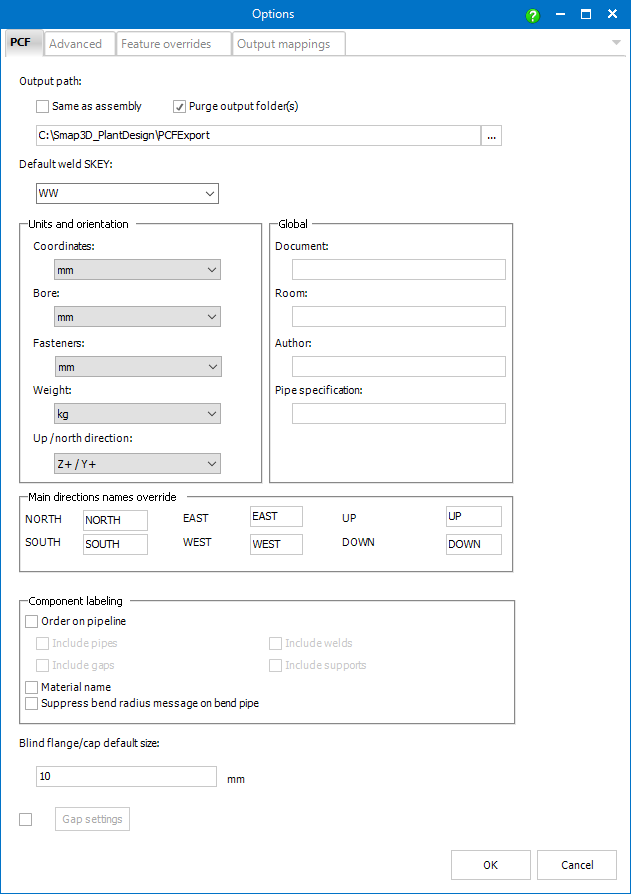

Output path is the location where the PCF files should be generated.

It is possible to set a constant path or - check Same as assembly - to generate the PCF file always to the current source data folder.

If Purge output folder(s) is checked, all the existing PCF files are deleted from the output path before generating.

Sets the SKEY

value which is assigned automatically to gaps recognized as welds.

![]()

Default weld SKEY and ISO_WELD_SKEY apply only to welds detected using welding gaps or to welds detected automatically between two components/pipes ends with explicitly defined (by direct edit or by ISO_CONNECTION custom property) welded (butt weld or socket weld) End Treatment.

![]() ISO_WELD_SKEY value set for a pipeline

path overrides the default weld SKEY value for all the welds on that pipeline path.

ISO_WELD_SKEY value set for a pipeline

path overrides the default weld SKEY value for all the welds on that pipeline path.

Coordinates - this setting is applied to coordinates, component

lengths, etc. Since the source data

already contains units, this setting determines the unit to which

all the dimensions will be recomputed in the resulting PCF files.

Bore - sets units for bore diameters. Since these dimensions

are taken from source data as dimensionless, for the proper result

the same units as used in source data should be used.

Fasteners - sets fasteners units. Since these dimensions are

taken from source data as dimensionless, for the proper result the

same units as used in source data should be used.

Weight - sets weight units. Since the weights are taken dimensionless

from source data, the same units as used in the source data should

be used for proper results.

Up / north direction - defines up direction within the source data and maps north direction. E.g. the value of Z+ / X- defines that the positive direction of the Z axis points up while the negative direction of the X axis points north.

The values entered in the Document, Room, Author and Pipe Specification fields can be handed over to the PCF file.

These settings manage the appearance of various labels in the resulting PCF files.

Order on pipeline determines whether labels with ordinal numbers should be included.

If the box is checked, ordinal numbers are generated for fittings automatically. Using the additional checkboxes it is possible to take into account also pipes, welds, gaps and supports.

![]() Ordinal numbers are not assigned

to special components such as split point, location point, flow arrow,

bolts, nozzles, messages, etc.

Ordinal numbers are not assigned

to special components such as split point, location point, flow arrow,

bolts, nozzles, messages, etc.

When Material name is checked, PCF files will also contain labels with part identifiers (part name typically) taken from ITEM_CODE (PCF feature).

![]() ITEM_CODE is mapped to the Title

file property by default. Mappings can be set/modified in Output

mappings section of the Smap3D PCFExport

options.

ITEM_CODE is mapped to the Title

file property by default. Mappings can be set/modified in Output

mappings section of the Smap3D PCFExport

options.

This setting is intended for finishing components (such as blind flanges or caps) which have only one pair of coordinate systems (INPUT_POINT, OUTPUT_POINT).

The second end point, which can be required for further processing, can be calculated using this setting.

![]() For the components containing

the TAPING_POINT or TAPPING_POINT coordinate

system this value is not taken into account.

For the components containing

the TAPING_POINT or TAPPING_POINT coordinate

system this value is not taken into account.

Using these settings it is possible to set the way Smap3D PCFExport manages gaps in the source data.

When the checkbox is not checked the gaps

are managed as follows:

if a gap is smaller than or equal to tolerance

it is ignored

if a gap is matching (± tolerance) the welding gap width defined

in the pipe specification, a weld component is added

otherwise a gap component is added.

With the checkbox checked the Gap settings is available. Using the Gap Settings Editor it is possible to adjust 4 ranges of gap length (+ one fixed). For each range any of the following actions can be set:

For each range any of the following actions

can be set:

Ignore - the gap is ignored (filled with a not-on-material-list

pipe)

Insert weld - weld component  is added

is added

Insert gap - gap component is added

Split drawing - split component ![]() is added,

i.e. the drawing will be split at this point.

is added,

i.e. the drawing will be split at this point.

The first range is automatically set from zero to the tolerance and the action is set to Ignore.

The upper limit of the previous rule is always tied to the lower limit of the following rules.

![]() For a gap matching (± tolerance) the welding gap width defined in the

pipe specification, a weld component is always added (independently on

the other settings).

For a gap matching (± tolerance) the welding gap width defined in the

pipe specification, a weld component is always added (independently on

the other settings).