![]()

The following requirements apply

to a special kind of components called collars, weldolets

or sockolets.

To be operated correctly with Smap3D Piping, these components must have two pairs of coordinate systems and two axes.

Each pair must contain an INPUT_POINT and OUTPUT_POINT coordinate system.

The first pair of coordinate systems indicates the intersection point between the center of the collar and the center of the main pipe to which this component should be placed.

Usually the main pipe is the straight section of the tee with the larger diameter.

CSInfo of the OUTPUT_POINT coordinate system must have set End Treatment to value of 10 (Butt Weld - Branch).

The x-axis of these

coordinate systems and the corresponding axis

must run in the direction

of the main pipe.

The x-axis of these

coordinate systems and the corresponding axis

must run in the direction

of the main pipe.

The Butt

Weld - Branch End Treatment, set in CSInfo,

ensures that the main pipe will not be divided in the

point where the collar is placed.

The Butt

Weld - Branch End Treatment, set in CSInfo,

ensures that the main pipe will not be divided in the

point where the collar is placed.

The second pair indicates the end of the component where the new branch should be created.

CSInfo of the OUTPUT_POINT coordinate system is optional.

If defined, it may have set any End Treatment but Butt Weld - Branch (ET=10).

The x-axis of these

coordinate systems and the corresponding axis

must run with the

component (flow

direction of the tee branch).

The x-axis of these

coordinate systems and the corresponding axis

must run with the

component (flow

direction of the tee branch).

The

proper coordinate systems and axes as

well as the CSInfo can be

created easily using Coordinate

System Wizard.

The

proper coordinate systems and axes as

well as the CSInfo can be

created easily using Coordinate

System Wizard.

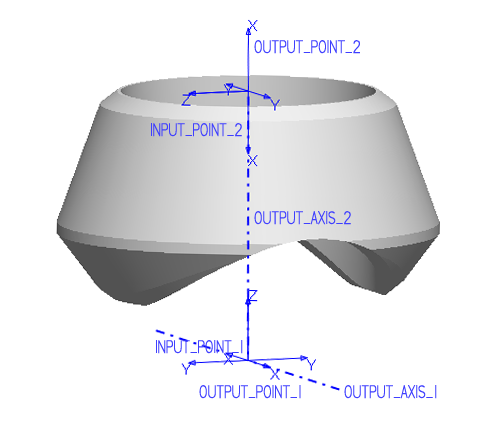

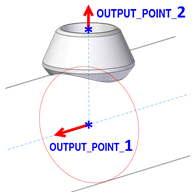

Example:

A collar fitting must contain coordinate systems and axes like:

INPUT_POINT_1 and OUTPUT_POINT_1 with a corresponding OUTPUT_AXIS_1 for the coordinate systems attached to the center of the main pipe.

The OUTPUT_POINT_1 coordinate system must contain proper End Treatment information (ET=10) in CSInfo.

(See the CS pair and axis in the bottom of the picture below)

INPUT_POINT_2 and OUTPUT_POINT_2 with a corresponding OUTPUT_AXIS_2 representing the point where a branch-pipe should be connected.

(See the CS pair and axis in the top of the picture below)