![]()

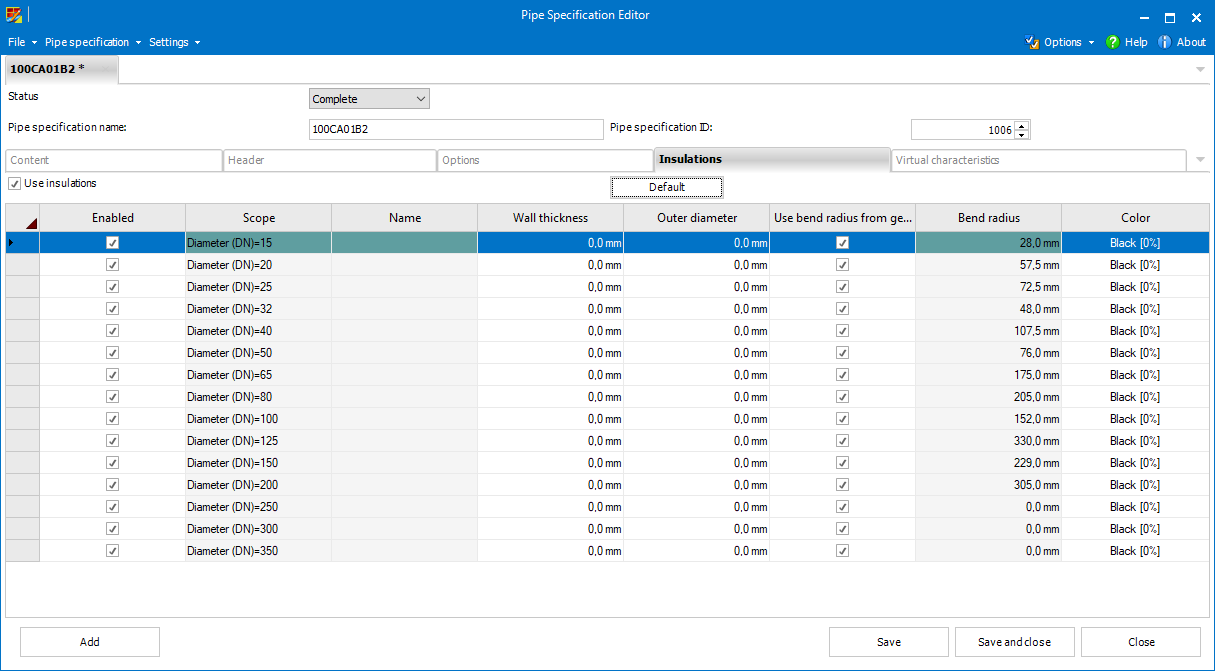

This section makes it possible to set parameters for generating insulations (insulation pipes).

It is possible to make basic settings easily by selecting Default. It adds a row for each size (diameter) used in the Content section and sets default values for the parameters described below.

A new row can also be added by Add (or context menu command). This action starts the Insulation Row Editor where the insulation parameters can be set.

The Insulation Row Editor can be also run by the Edit in context menu intended to edit an existing row.

The unwanted rows can be removed using Remove in context menu.

Remove unused scopes removes all rows which have set scopes (see below) containing pipe specification parameter values that are not used in the current content of the respective pipe specification (e.g. all components of a specific diameter have been removed from the pipe specification).

This checkbox enables generating insulation for the current pipe specification in general; i.e. if it is not checked, the commands for generating insulations in Smap3D Piping are not available for a pipeline generated using such pipe specification.

Activates/deactivates the respective insulation row; i.e. determines whether an insulation of the specified parameters can (or cannot) be generated on respective pipelines (those generated using the respective pipe specification and scope).

Defines the pipe specification parameter (or a combination of parameters) for which the insulation parameters are set.

The scope can be set within the Insulation Row Editor by selecting values of the pipe specification parameters.

When there is no value selected for any parameter, the scope is set to Global. It defines insulation for all the pipe specification parameters which do not have it defined explicitly (within an individual row).

In case

more insulations (rows) are defined for the same scope, the one to be

used must be selected by the user when Generating

Insulation.

In case

more insulations (rows) are defined for the same scope, the one to be

used must be selected by the user when Generating

Insulation.

Name is used to tell apart non-unique insulations (insulations with the same scope) while Generating insulations.

Thickness of the generated insulation.

Outer diameter of the generated insulation.

When the

Wall Thickness value is changed, the Outer Diameter value is recomputed

automatically.

When the

Wall Thickness value is changed, the Outer Diameter value is recomputed

automatically.

When this option is checked the bend radius for the insulations is taken from the generated pipes. It is useful to reach the uniformity of the finished pipeline.

The radius of a bend on generated insulations.

Color of generated insulations.

The Insulation Row Editor makes it possible to define custom properties that are written to the generated insulation part files.

Apart from editing properties listed above, you can also:

Use material for insulation

This option allows to set custom or prepared material for insulation generated using current pipe specification.

If Use

material for insulation is checked, the face

style will not be overridden! Face Style needs to be disabled for Color

of Material to take place.

If Use

material for insulation is checked, the face

style will not be overridden! Face Style needs to be disabled for Color

of Material to take place.

Apply physical properties

This option applies all physical properties of a chosen material. Material is recalculated. Selected material is listed in CAD material and in isometric.