![]()

This option can be found in Isometric options in Advanced tab. Write Repeatability Info causes that during a repeated isometric generation (after changes in 3D) a component or a weld seam, has the same number in the isometric drawing, regardless of the changes made to the other components of the pipeline.

This option is intended to work with Repeatibility Return report defined in I-Configure for each style.

Isometric reads assembly and writes Unique Identificator to the occurrence properties of the components during this reading phase.

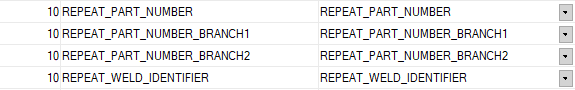

In the step 3, select a style with repeatability return correctly set (style should have value OK). After the drawing is complete, repeatability return report is processed and new occurrence properties are written to parts and welds on selected pipeline, REPEAT_PART_NUMBER to parts and REPEAT_WELD_NUMBER to welds with corresponding number.

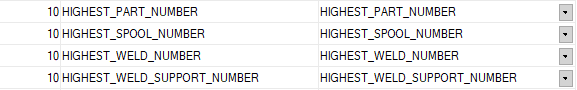

The actual pipeline now has values HIGHEST_PART_NUMBER and HIGHEST_WELD_NUMBER.

Now if there is a new part added on the pipeline it will have a number according to its placement on pipeline starting with the next number after HIGHEST_*_NUMBER.

Assembly needs to be saved at this point to conserve the newly written information.

Assembly needs

to be saved in order to save the information!

Assembly needs

to be saved in order to save the information!

Weld repeatability works by writing virtual characteristic to the weld part (if it exist) or to the connected parts and pipes. Not only the weld number is written but also its assigned SKEY. If the part that carry the weld information is later replaced by Piping or manually, the information about the connected weld is lost.

The names of the virtual characteristics start with ATTACHED_WELD for welds created by Isogen library and CONNECTED_WELD for the welds inserted by Isometric based on the existence of welding gaps. If the weld part exists, the name of the virtual characteristic is REPEAT_WELD_IDENTIFIER and it should be mapped directly to the PCF value of the same name (see the mapping below).

The isometric step 2 screen shows the welds deducted from existence of above mentioned virtual characteristics.

In Isometric options Isometric Write repeatability has to be checked.

Several values needs to be mapped for the PCF file, depending on what functions are requested. The relevant values are:

HIGHEST_PART_NUMBER

REPEAT_PART_NUMBER

REPEAT_PART_NUMBER_BRANCH1

REPEAT_PART_NUMBER_BRANCH2

HIGHEST_WELD_NUMBER

HIGHEST_WELD_SUPPORT_NUMBER

REPEAT_WELD_IDENTIFIER

SPOOL_IDENTIFIER

HIGHEST_SPOOL_NUMBER

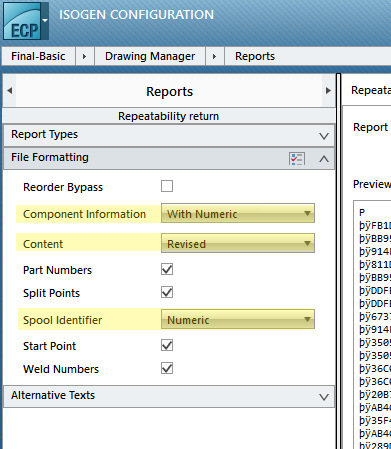

For correct use of repeatability information in Isometric, a style in I-Configure must have the Repeatability return report in the File Formatting section configured exactly as follows (for full repeatability):

- Component Information > With Numeric (must not be empty or off)

- Content > must be set to Revised

- Spool Identifier > Numeric (must not be empty or off)

- Part numbers, Split points, Weld numbers, Start point - checked (specific function can be disabled by unchecking relevant checkbox)

If other values are selected from the existing list fields, Isometric

cannot work with them correctly!

If other values are selected from the existing list fields, Isometric

cannot work with them correctly!

It is recommended

to draw one style at a time.

It is recommended

to draw one style at a time.